ŠMT a.s. - Heavy-duty boring & milling machines & lathes for large workpieces

Our machines are traditionally known for their presicion and quality what is related with the using of the latest technologies. Here is an overview of our horizontal boring and milling machines and horizontal lathes, which are the result of experiences and development gained for more than one hundred years.

Horizontal boring and milling machines

Horizontal boring and milling machines ŠMT are successful all over the world, since they are capable to machine accurately and efficiently large workpieces of complex shapes, such as turbines, parts of windmills or large motor blocks.

Milling machines

The compact design of ŠMT FC milling machines ensures maximum performance and allows for efficient machining of medium-sized components.

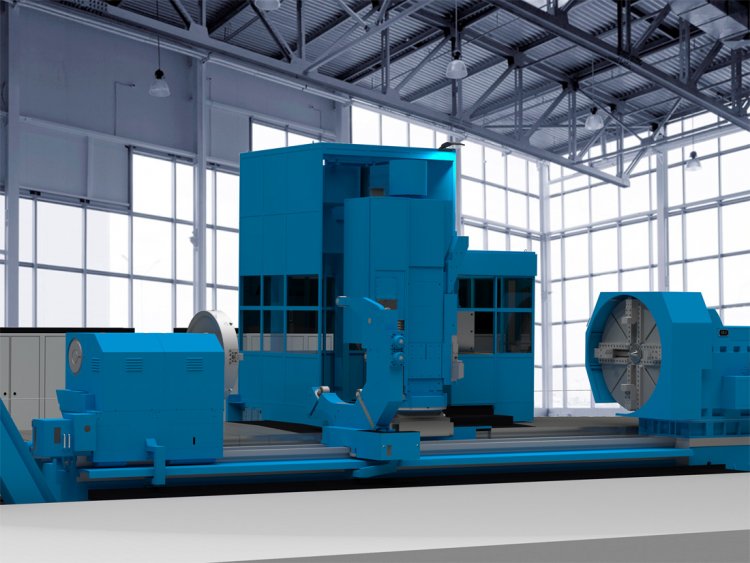

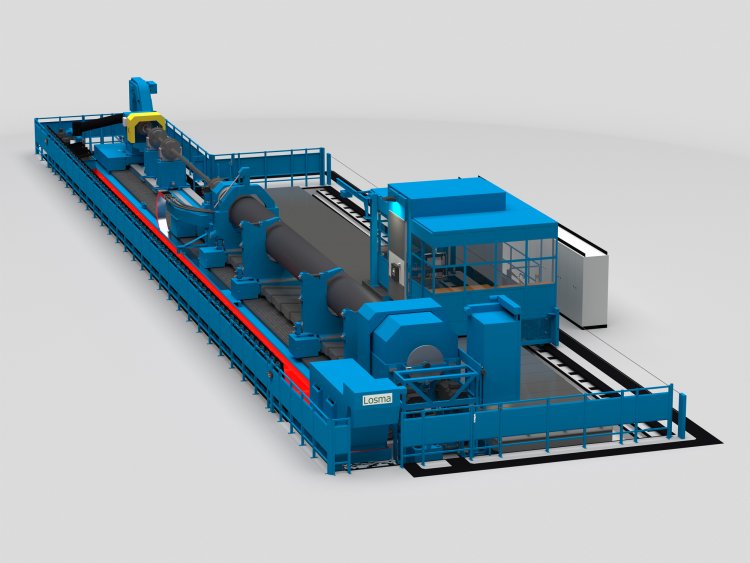

Universal horizontal lathes

Heavy horizontal lathes ŠMT equipped with NC controlling enable effective and precise machining of axial workpieces. Supplied with a wide range of accessories they can machine parts like crankshafts or turbine rotors including slotting.

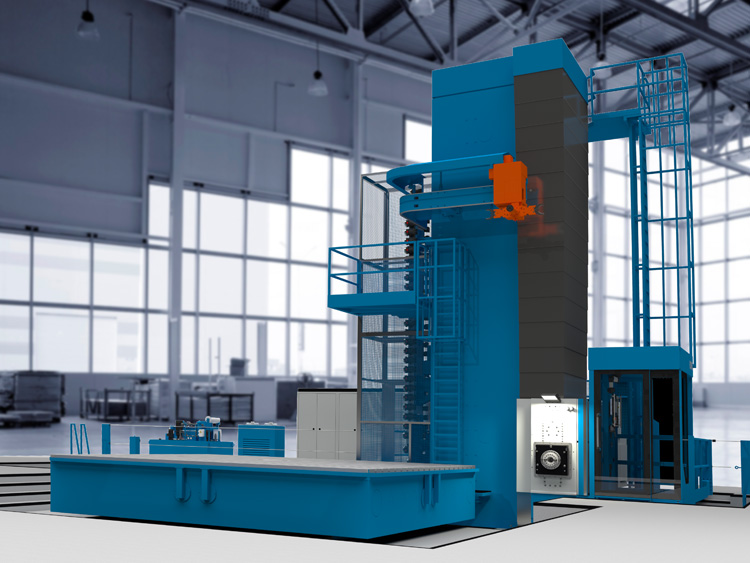

Portal Milling Machines Working station

With a portal milling machine, large and heavy workpieces can be machined with maximum precision.

Special machine tools

Special working area of horizontal boring and milling machines and horizontal lathes for machining of workpieces with some specifical requirements, as the crank shafts, generators or motors.

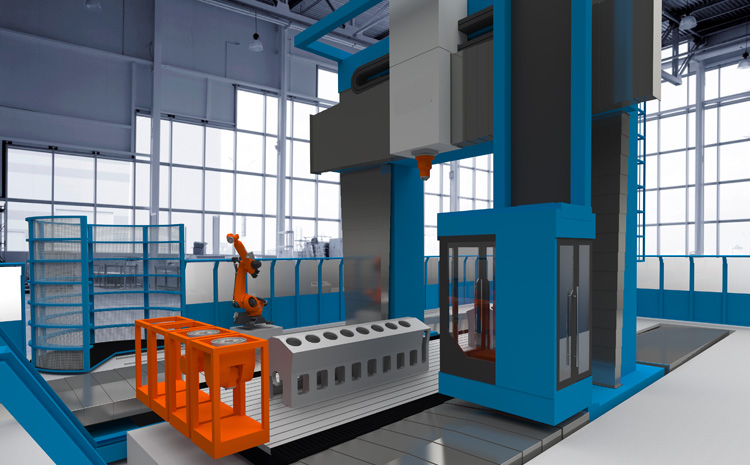

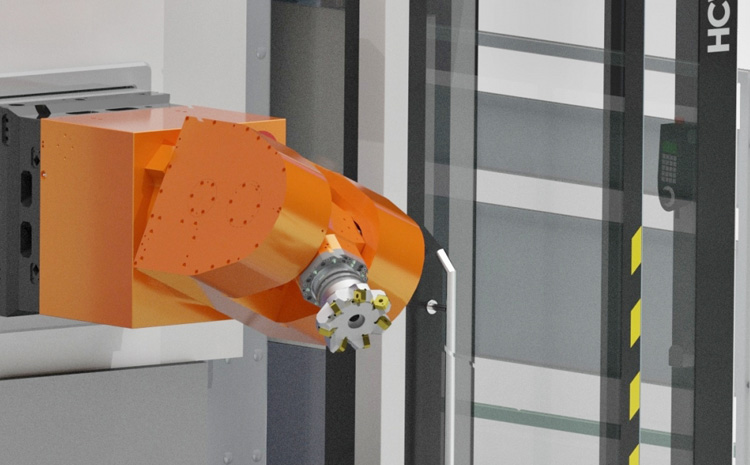

Machine Accessories

ŠMT offers various accessories allowing complete machining of generators for all kinds of power plants, turbine rotors or crank shafts of four-stroke or two-stroke motors. Automatic or robotic change of tools help customer with saving time required for machining.